Pull Rod Cubic Press

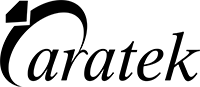

The PULL ROD CUBIC PRESS is applicable to the research and development, the production and manufature of the super-hard materials, including the artificial diamond, the monocrystal and glomerocryst of CBN (cubic boron nitride), and the synthesized compounds (such as PCD,PCBN) and etc. Aiming at the customer individual requirements of customization, we are able to provide the whole set of auxiliaries and hydraulic solutions.

Advantages:

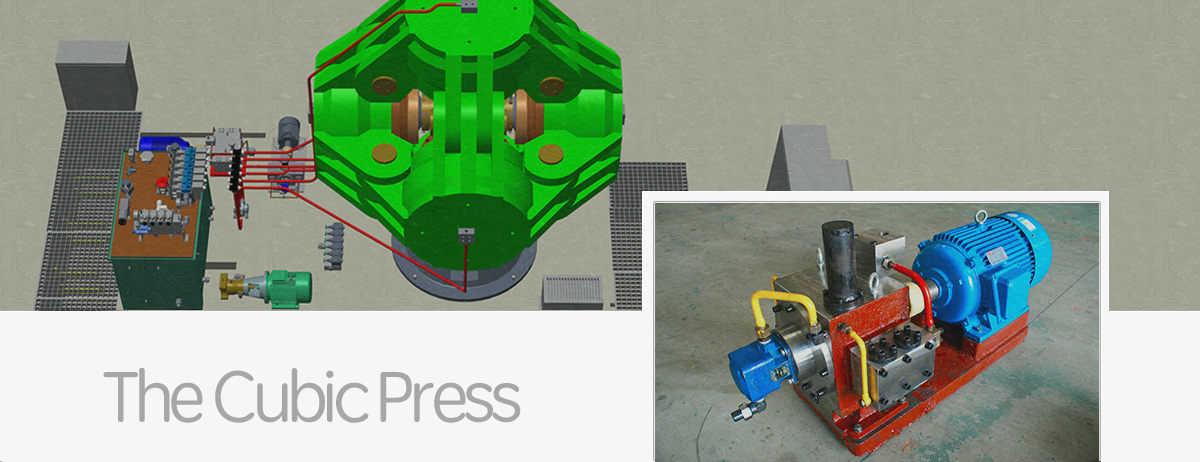

- With advanced pull rod type structure, the equipment will have high centering accuracy and repeatability, stable pressure field and adjustable temperature field. Hydraulic servomotor controls pressure of the chamber, which can make the fluctuation less than 0.05MPA and centering accuracy less than 0.05mm;

- Precise control system, Controlled constant-temperature cooling system, Hydraulic servo pressure control system, Reciprocating-type supercharger, ultrahigh pressure relief valve, Large and small piston rod structure, High-accuracy displacement transducer Multi-machine remote control

- Forged parts with long service life; Easy to operate and maintain

The Models we have

| Model | Press (Rod) | Open Size (mm) | Stroke (mm) |

| 3200T | 6*31.83MN | 865 | 110 |

| 3600T | 6*35.61MN | 912 | 110 |

| 4100T | 6*40.99MN | 965 | 120 |

| 4600T | 6*45.26MN | 1020 | 120 |

| 5100T | 6*49.75MN | 1080 | 130 |

| 5800T | 6*57.70MN | 1140 | 130 |

Applicable to: lab-grown diamond, CBN monocrystal, PCD, PCBN, PDC, large-size diamond

Color Enhancement

With the development of techniques, diamond became available in the form of extended thin films and free-standing plates or windows. With this technology, it is possible to make large sized diamonds but with color grade around I-J. As the most advanced technology supplier, our company can supply diamond color whitening technology changing color to D, E, F, G by HPHT treatment.

We deliver turnkey HPHT treatment project particularly for diamond color whitening at customer’s premises, including the following aspects:

1)Optimize equipment configuration of HPHT cubic press for diamond color whitening

2)Customer’s workshop foundation design and optimum layout of water and power supply

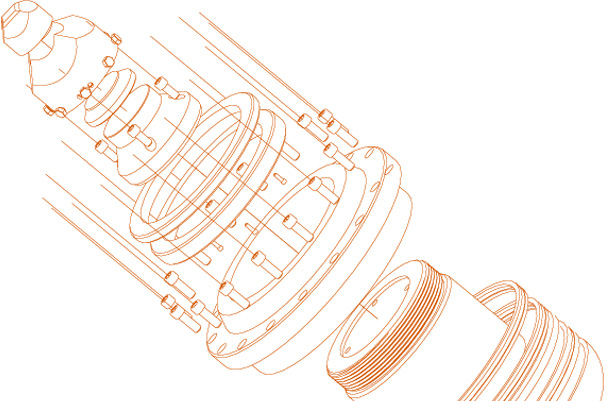

3)Inside cell design including anvil and cube full dimensions for diamond color whitening

4)Special pyrophyllite cube supply for diamond color whitening

5)Installation and testing HPHT cubic press

6)Operation of HPHT cubic press

7)Teaching and training of customer’s engineers

8)Technical support and maintenance